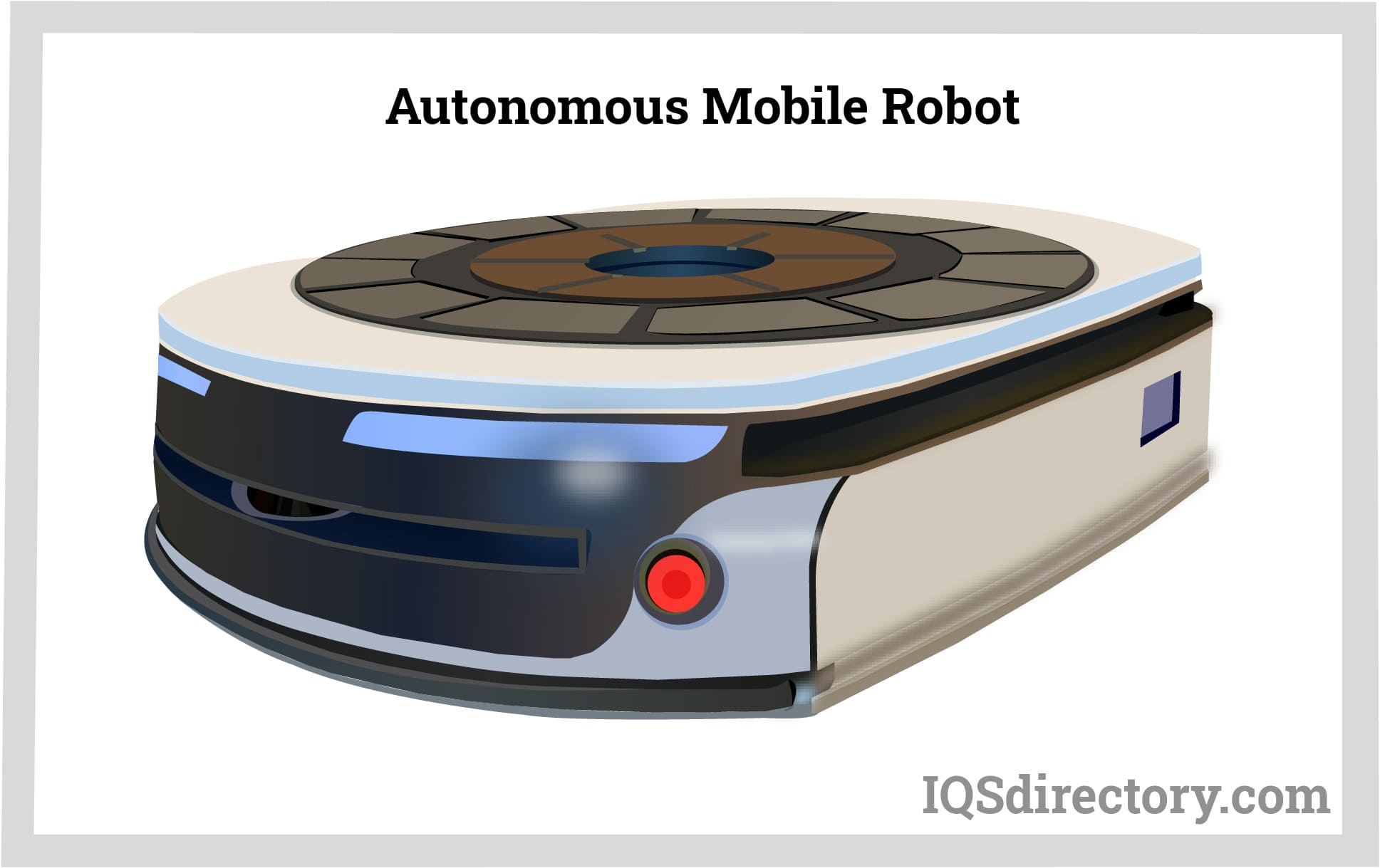

A self-driving computer- or pc-controlled forklift is an AGV forklift, sometimes known as an ALT. So said, driverless forklifts operate independently to complete tasks as directed by a centralized controller for the fleet of automatic forklifts. A computer-controlled device, an automated guided vehicle (AGV) forklift, carries and executes many tasks without human assistance or direction. They are a component of an intricate and difficult technical system composed of peripherals, robotics, and computer programming. Read More…

We invented the AGV in 1954 and offer the most affordable & versatile AGV capabilities. Our AGVs automatically transport pallets, racks, bins, totes, rolls, boxes, racks, etc. in all types of manufacturing and warehouse facilities. Our tape/target/structure-free, ‘virtual path’ navigation requires no floor path maintenance and does not use/require line-of-sight to often blocked building ...

America in Motion was founded in 2007 with a mission to bring customized automated vehicle designs and solutions to the masses. Serving customers in the fibers, paper, automotive, food, consumer products, heavy equipment, and general manufacturing. Our team specializes in fully customizable AGVs but also offers the option to build an automated vehicle by using a simplified modular approach (also...

With over 1700 mobile robotics deployed worldwide and with over 30 million miles accumulated, Oceaneering Mobile Robotics (OMR) delivers best-in-class solutions with the lowest total cost without sacrificing performance. For over 30 years, OMR has been a trusted partner of exclusive brands in the automotive, healthcare, manufacturing, and (intra-) logistics industries.

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

For over 30 years, companies have turned to RedViking for ways to increase throughput and minimize infrastructure. We are a leading AGV manufacturer, and our AGVs are efficient and user-friendly. Our AGV solutions are cleaner, more sustainable, and require less infrastructure than traditional conveyance methods. We can provide full custom design tooling for your AGV so it meets every requirement...

IDC Corporation produces a line of Automated Guided Carts (AGCs) for various industrial applications, including standard product line carts and custom-designed systems tailored to specific customer needs. The various models are built on a common control architecture that support various mechanical configurations, and support operations ranging from simple delivery loops to sophisticated...

More AGV Forklift Manufacturers

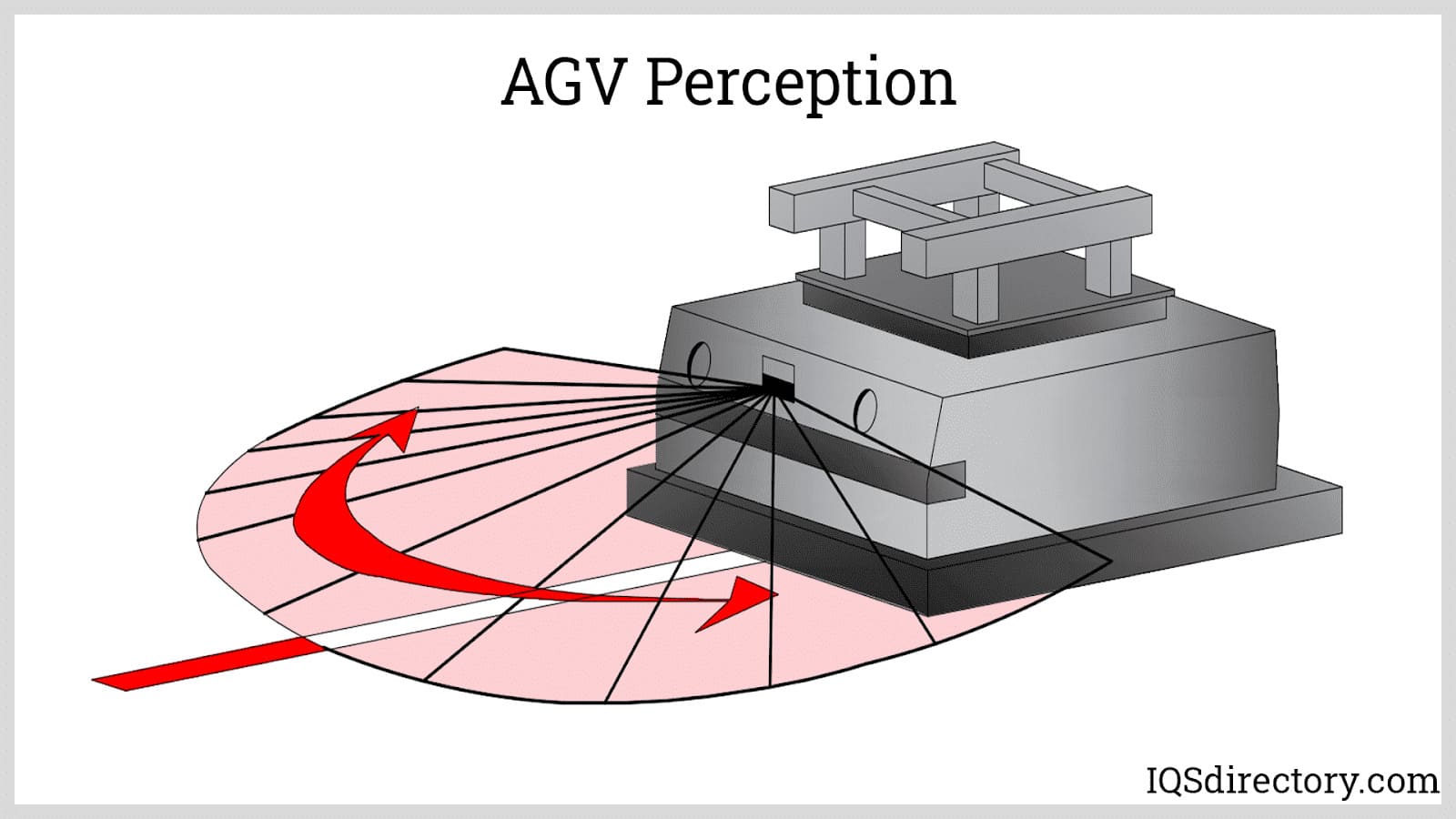

For pickup and delivery from the ground and elevations like conveyors and storage racks, AGV forklifts can handle a wide range of load sizes. They consist of outrigger and counterbalance designs with weight capacities of at least 10,000 lbs. On AGV forklifts, several guidance technologies are employed, including magnetic tape, precision-guided vehicle technologies, organic navigation, and magnetic spots. Therefore, selecting the appropriate navigation system for an automatic guided vehicle forklift is essential to its success.

How AGV Forklifts Work

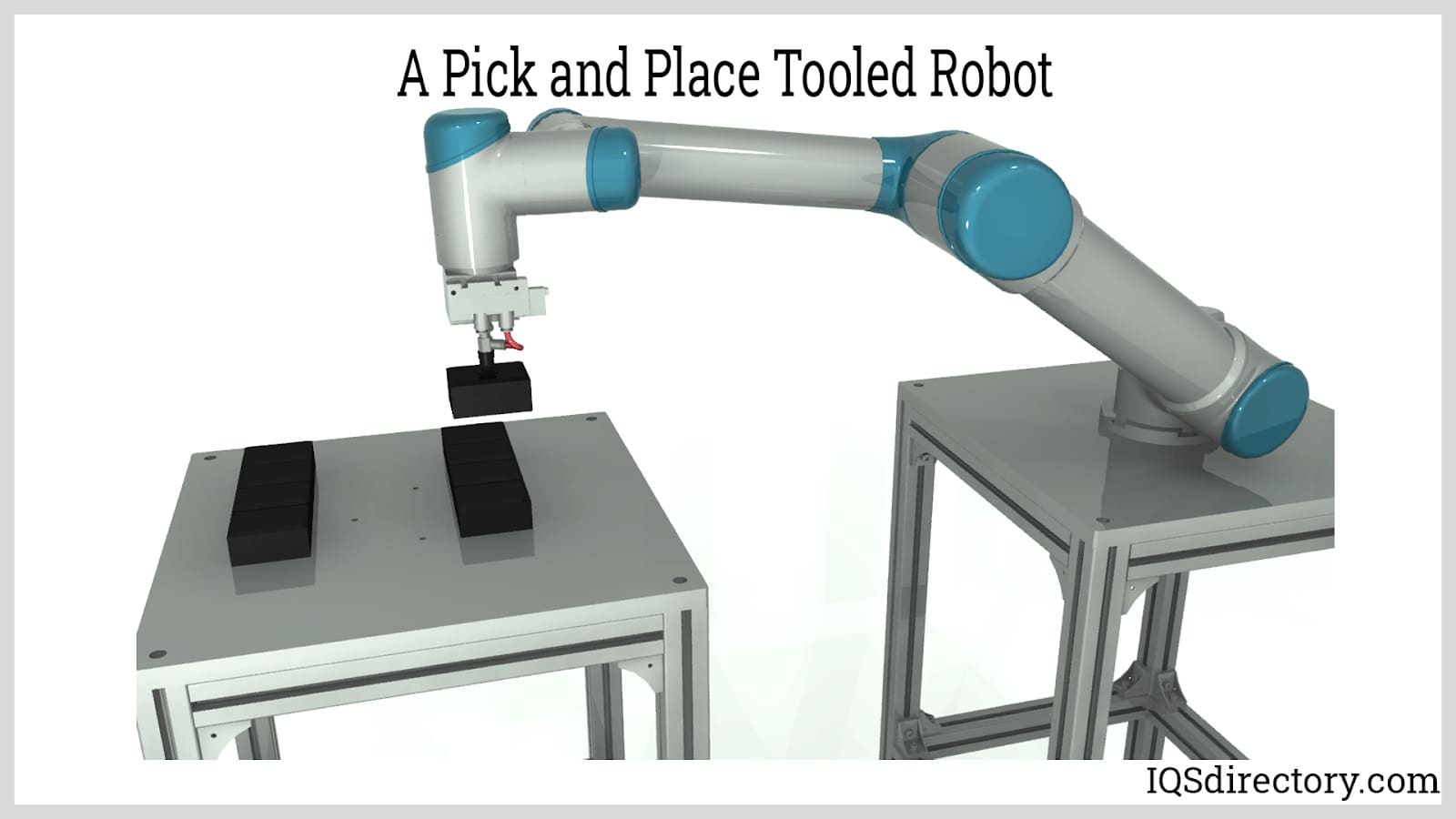

- The central controller sends a mission to the AGV forklift. For example, if the instruction is to "carry the pallet Y from location A to position B."

- The controller and robotic forklifts communicate through Wi-Fi.

- The AGV forklift makes its way to position A via navigation. The forklift can navigate a route to get to point A using various AGV navigation techniques, such as natural navigation and laser navigation.

- Automated forklifts utilize several AGV sensors for various purposes, including navigation, safety, material handling, etc.

- Of course, when we talk about AGV, safety is among the primary topics. For example, automated forklifts are fitted with safety sensors and other technologies to keep them from colliding with barriers (people or things).

- When the automated forklift truck gets to point A, it picks up the material and moves it safely to point B while always using the above navigation and safety equipment.

- When the task is complete, the forklift notifies the central system that the previous task has been completed and is ready for a new task.

As previously noted, AGV forklifts operate on a complicated system controlled by computer software and sensors. Therefore, they not only do away with the necessity for a worker but also tend to perform quite precisely. The following is a list of the characteristics of AGV forklifts that are popular across all industries:

- The AGV forklift's front-facing mast component, intended to allow for vertical and horizontal movement, is managed by software that runs through the machine's system.

- The machine's operating system is given a predetermined path to prevent the AGV forklift from straying from its intended course.

- The AGV forklift's speed is controlled by the sensor system, which uses front-end sensors.

- AGV forklifts contain a yellow zone to guarantee worker safety; if an employee enters it, the device slows down. Additionally, the machine features a red zone wherein if the worker moves, the machine will stop entirely.

- The AGV forklifts hoist the goods and move using a network of visual and audio cues, respectively.

Types of AGV Forklifts

AGV Pallet Stacker Forklift

The same job as a pallet mover is performed by AGV forklift stackers but without restrictions on vertical motion and weight capability. Over a ton can be lifted several meters onto a pallet rack using a highly engineered AGV forklift stacker. They lack the unique characteristics of an automatic guided forklift but perform similarly to a forklift.

AGV Forklift with Counterbalance

A counterbalanced automatic guided forklift has a large payload capacity since the mass of its cargo is balanced against it. The AGV forklift's counterbalance weight is either an additional cast iron piece or a battery pack at the back. In addition to having a large payload capacity, counterbalanced automatic guided forklifts can lift objects higher than pallet stackers, independent of the weight of their load. The main operations where counterbalanced automatic guided forklifts are employed include transporting stored objects to and from storage facilities and shipping and receiving. Counterbalanced automatic guided forklifts are heavier and bigger to accommodate their lifting capabilities, necessitating a greater turning radius.

AGV Reach Forklifts

Similarly to straddle AGV forklifts, AGV reach forklifts are built to operate in warehouses with tight aisles and include outer legs for added load support. The mast on an automatic guided reach forklift stretches the prongs outside the vehicle's footprint to increase maneuverability. In addition, reach AGV forklifts have the advantage of working with double-deck pallets.

Choosing the Correct AGV Forklift Supplier

To make sure you have the most {positive/constructive/productive/beneficial} outcome when purchasing AGV Forklift from an AGV Forklift Manufacturer, it is important to compare at least 5 or 6 Suppliers using our list of AGV Forklift suppliers. Each AGV Forklift Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each AGV Forklift company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple AGV Forklift companies with the same message.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches