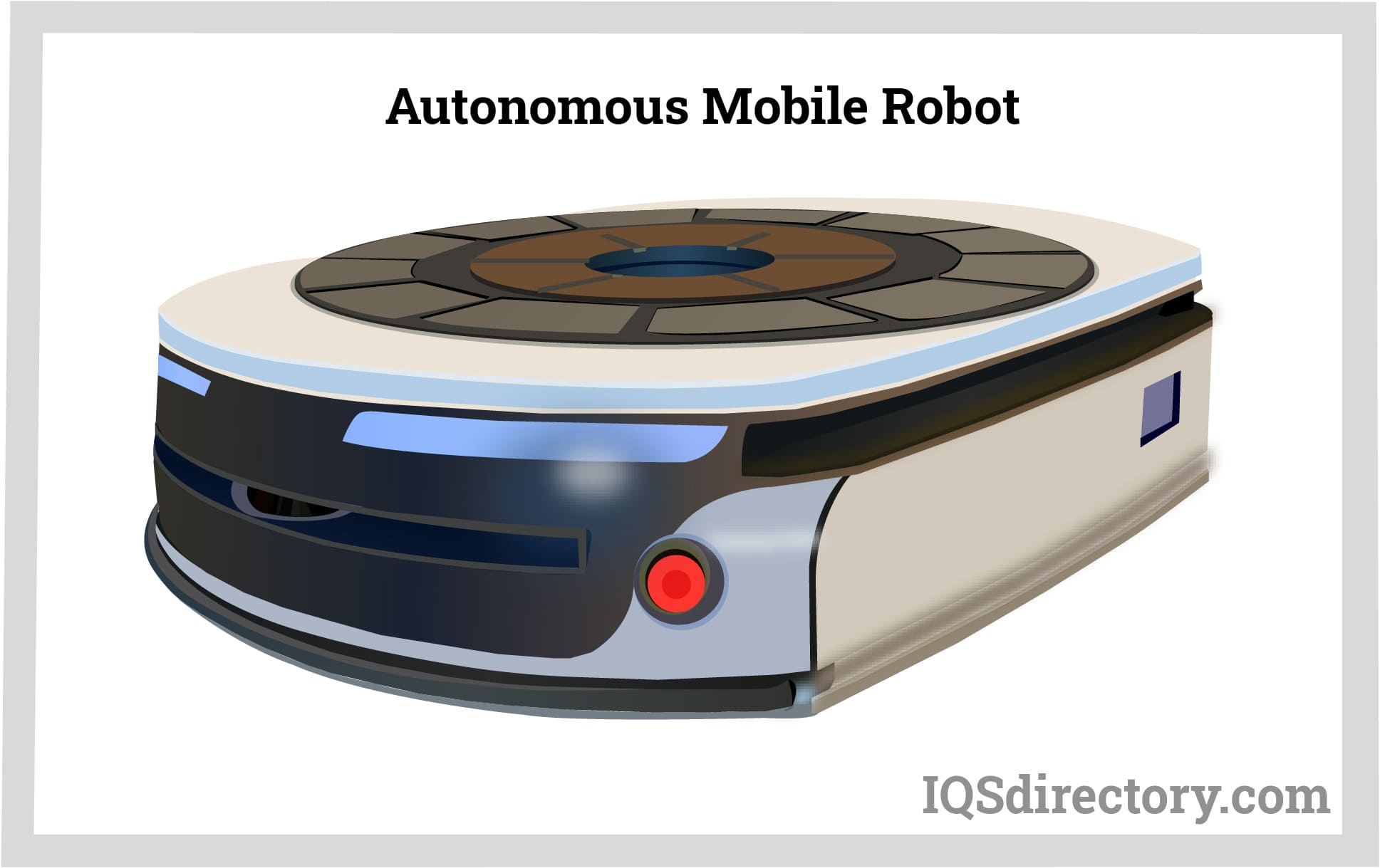

Automated guided vehicles (AGVs) are robotic systems that move and transport materials, products, or equipment in a warehouse or a manufacturing facility without human intervention. The use of AGV robots has revolutionized the logistics industry, offering a safer, more reliable, and cost-effective way of moving goods. Read More…

We invented the AGV in 1954 and offer the most affordable & versatile AGV capabilities. Our AGVs automatically transport pallets, racks, bins, totes, rolls, boxes, racks, etc. in all types of manufacturing and warehouse facilities. Our tape/target/structure-free, ‘virtual path’ navigation requires no floor path maintenance and does not use/require line-of-sight to often blocked building ...

America in Motion was founded in 2007 with a mission to bring customized automated vehicle designs and solutions to the masses. Serving customers in the fibers, paper, automotive, food, consumer products, heavy equipment, and general manufacturing. Our team specializes in fully customizable AGVs but also offers the option to build an automated vehicle by using a simplified modular approach (also...

With over 1700 mobile robotics deployed worldwide and with over 30 million miles accumulated, Oceaneering Mobile Robotics (OMR) delivers best-in-class solutions with the lowest total cost without sacrificing performance. For over 30 years, OMR has been a trusted partner of exclusive brands in the automotive, healthcare, manufacturing, and (intra-) logistics industries.

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

For over 30 years, companies have turned to RedViking for ways to increase throughput and minimize infrastructure. We are a leading AGV manufacturer, and our AGVs are efficient and user-friendly. Our AGV solutions are cleaner, more sustainable, and require less infrastructure than traditional conveyance methods. We can provide full custom design tooling for your AGV so it meets every requirement...

IDC Corporation produces a line of Automated Guided Carts (AGCs) for various industrial applications, including standard product line carts and custom-designed systems tailored to specific customer needs. The various models are built on a common control architecture that support various mechanical configurations, and support operations ranging from simple delivery loops to sophisticated...

More AGV Robot Manufacturers

The first AGV robot was introduced in the 1950s by Barrett Electronics in the United States. The first AGVs were designed to transport materials from one location to another, and they were guided by wires embedded in the floor. The AGV technology has evolved over the years, and now AGVs can operate without any human intervention and can navigate through complex environments.

Components of AGV Robots

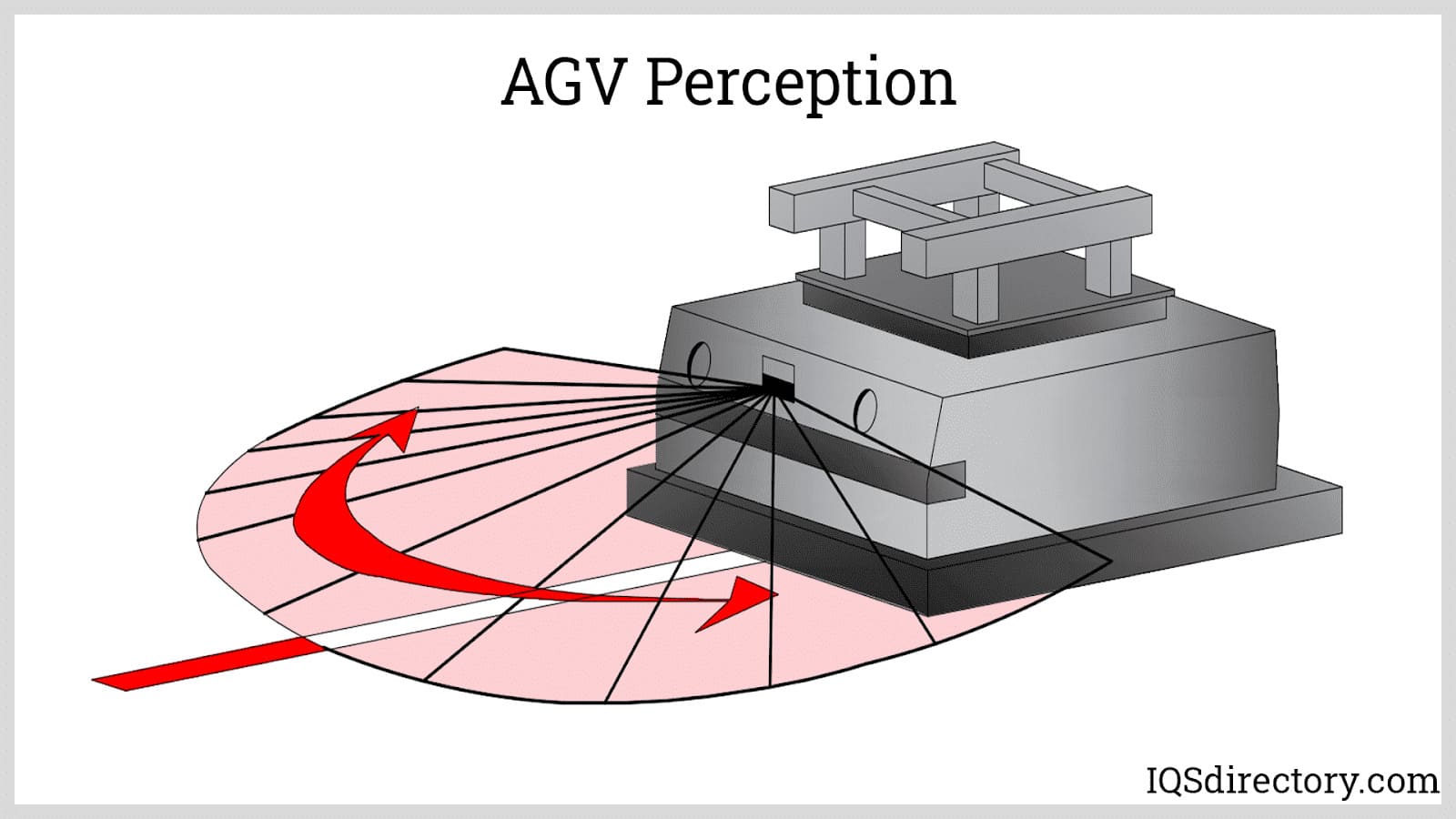

AGV robots are composed of several components, including navigation systems, sensors, control systems, power supply, interface, and mobility systems. The navigation systems are responsible for guiding the AGV robots through their environment, and the sensors detect any obstacles in their path. The control systems coordinate the movement of the AGV robots, and the power supply provides the energy required for the AGV robots to operate. The interface is responsible for communication between the AGV robot and its environment, and the mobility systems allow the AGV robot to move.

Variations of AGV Robots

There are different types of AGV robots, including guided AGVs, self-driving AGVs, and hybrid AGVs. Guided AGVs are guided by wires or magnets embedded in the floor, while self-driving AGVs are autonomous and can navigate through complex environments using sensors and mapping technology. Hybrid AGVs combine the features of guided and self-driving AGVs.

Limitations and Negatives of AGV Robots

AGV robots have some limitations, including limited flexibility, high initial investment, and limited adaptability. AGV robots can be programmed to perform specific tasks, but they are not flexible enough to adapt to new tasks or changes in the environment. AGV robots require a significant initial investment, which can be a barrier to entry for some businesses. Finally, AGV robots are limited in their adaptability, and they cannot handle complex tasks that require human dexterity.

However, there are potential challenges that may arise with the increasing adoption of AGV robots. One concern is the displacement of human workers, as AGV robots may replace some manual labor tasks. Another concern is the potential for hacking or malfunctioning of AGV robots, which could result in safety risks or loss of productivity.

Benefits of AGV Robots

Despite their limitations, AGV robots offer many benefits, including increased efficiency and productivity, enhanced safety, and reduced labor costs. AGV robots can operate around the clock, which increases the speed and efficiency of material handling processes. They also eliminate the risk of accidents associated with manual labor, which enhances workplace safety. AGV robots can perform tasks that would otherwise require human intervention, reducing the need for labor and reducing labor costs.

Applications of AGV Robots

AGV robots are used in various industries, including manufacturing and production, warehousing and distribution, healthcare, and retail. These specific applications are discussed below in greater detail.

Manufacturing and Production

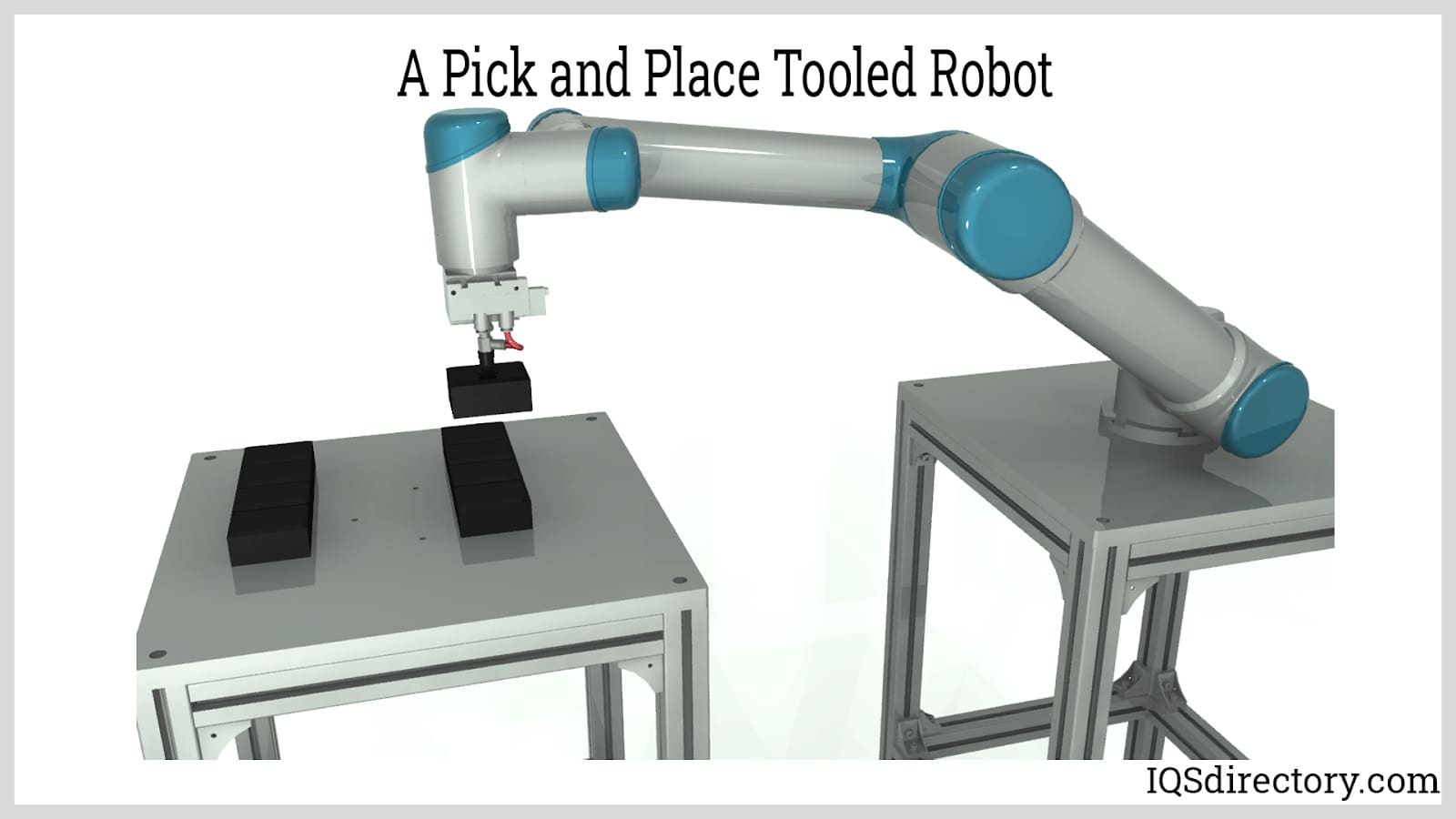

In the manufacturing and production industry, AGV robots are used for material handling and transportation of products between different stages of the production process. AGV robots can be programmed to transport raw materials, semi-finished products, or finished products, which reduces the need for manual labor and speeds up the production process. AGV robots are also used for assembly line automation, where they transport parts to different workstations and perform some assembly tasks. This helps to increase efficiency, reduce human error, and improve product quality.

Warehousing and Distribution

In warehousing and distribution, AGV robots are used for storage, retrieval, and transportation of products within a warehouse or distribution center. AGV robots can navigate through aisles and corridors, pick up and drop off products, and transport them to the desired location. This improves the speed and accuracy of material handling processes, reduces labor costs, and minimizes the risk of accidents associated with manual labor.

Healthcare

In healthcare, AGV robots are used for transportation of medical equipment, supplies, and medication between different parts of the hospital. AGV robots can be programmed to transport items between the pharmacy, laboratory, patient rooms, and operating rooms, which reduces the need for human labor and increases the speed and accuracy of the delivery process. AGV robots also help to minimize the risk of contamination and reduce the risk of injury to healthcare workers who may need to move heavy or bulky equipment.

Retail

In retail, AGV robots are used for the transportation of products from the storage room to the sales floor. AGV robots can be programmed to navigate through the store aisles, pick up products, and transport them to the desired location. This reduces the need for manual labor, speeds up the restocking process, and improves the accuracy of inventory management.

The Future of AGV Robots

The future of AGV robots is bright, with advancements in technology and increased adoption rates. The integration of artificial intelligence and machine learning will enable AGV robots to learn and adapt to new environments and tasks, improving their flexibility and adaptability. As AGV robots become more affordable, businesses of all sizes will be able to adopt the technology, leading to increased efficiency and productivity across industries. In the future, AGV robots may also become more customizable, allowing for more tailored solutions to specific business needs.

Choosing the Right AGV Robot Manufacturer

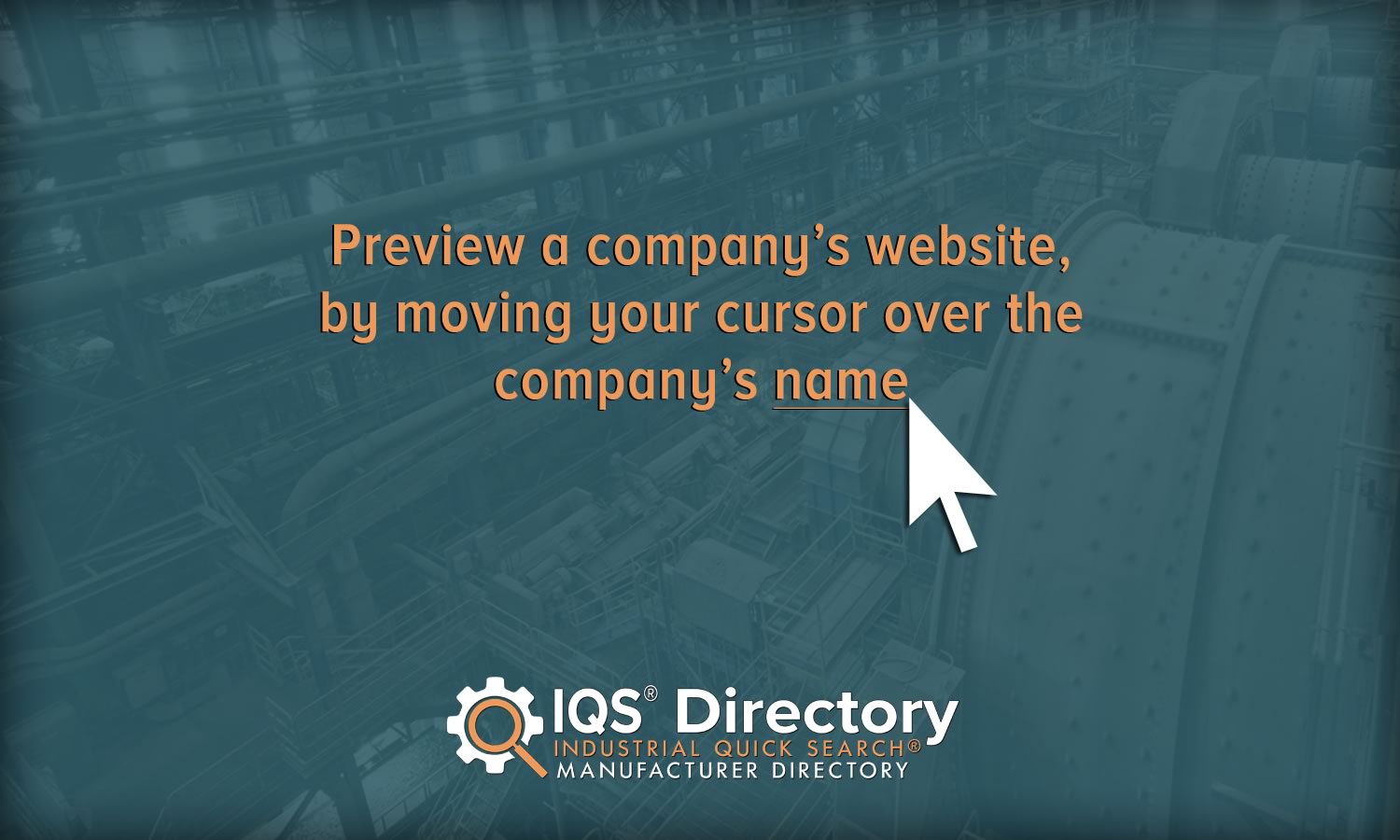

To ensure you have the most productive outcome when purchasing AGV robots from an AGV robot manufacturer, it is important to compare several companies using our directory of AGV robot manufacturers. Each AGV robot manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each AGV Robots business using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple AGV robot companies with the same form.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches