They were designed originally for industrial market lifting and transportation, but are now used by a variety of fields including aerospace, automotive, general manufacturing, food processing, packaging, mail and newspaper, metals and plastics. Automated guided vehicles have more specifically designed vehicles in their family, such as the automatic guided vehicles that are used for material sorting, storage, transportation, delivery and assembly and depending on their intended application can range greatly in size and capability. Read More…

We invented the AGV in 1954 and offer the most affordable & versatile AGV capabilities. Our AGVs automatically transport pallets, racks, bins, totes, rolls, boxes, racks, etc. in all types of manufacturing and warehouse facilities. Our tape/target/structure-free, ‘virtual path’ navigation requires no floor path maintenance and does not use/require line-of-sight to often blocked building ...

America in Motion was founded in 2007 with a mission to bring customized automated vehicle designs and solutions to the masses. Serving customers in the fibers, paper, automotive, food, consumer products, heavy equipment, and general manufacturing. Our team specializes in fully customizable AGVs but also offers the option to build an automated vehicle by using a simplified modular approach (also...

With over 1700 mobile robotics deployed worldwide and with over 30 million miles accumulated, Oceaneering Mobile Robotics (OMR) delivers best-in-class solutions with the lowest total cost without sacrificing performance. For over 30 years, OMR has been a trusted partner of exclusive brands in the automotive, healthcare, manufacturing, and (intra-) logistics industries.

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

For over 30 years, companies have turned to RedViking for ways to increase throughput and minimize infrastructure. We are a leading AGV manufacturer, and our AGVs are efficient and user-friendly. Our AGV solutions are cleaner, more sustainable, and require less infrastructure than traditional conveyance methods. We can provide full custom design tooling for your AGV so it meets every requirement...

IDC Corporation produces a line of Automated Guided Carts (AGCs) for various industrial applications, including standard product line carts and custom-designed systems tailored to specific customer needs. The various models are built on a common control architecture that support various mechanical configurations, and support operations ranging from simple delivery loops to sophisticated...

More Automated Guided Vehicles Manufacturers

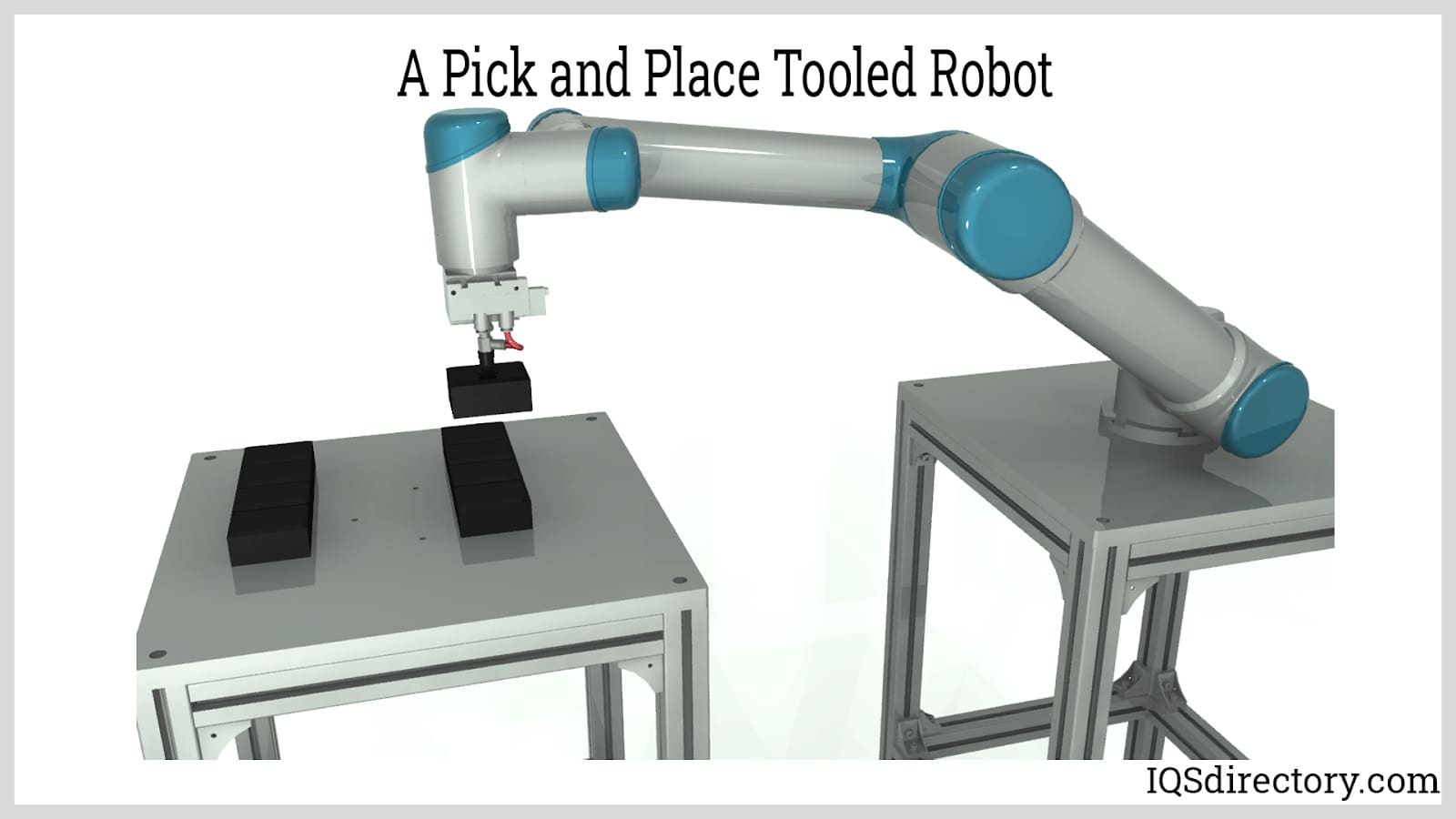

Simple towing vehicles can be used for heavy pallet load transportation while complex material handling robots can be designed to assist in small product assembly. Trailer loading, finished product handling and tooling change out are further uses of AGVs in many applications.

In both light and heavy manufacturing processes, guided vehicles can provide highly repetitive and reliable actions, allowing for improved operation flow and output. Using AGV systems in a manufacturing facility helps to increase overall efficiency and lower labor costs.

The vehicles are able to manage tasks that typically require manual intervention with more speed and capacity thus reducing the amount of time wasted in operations. The vehicles typically run from industrial batteries or electricity although power requirements will change according to application.

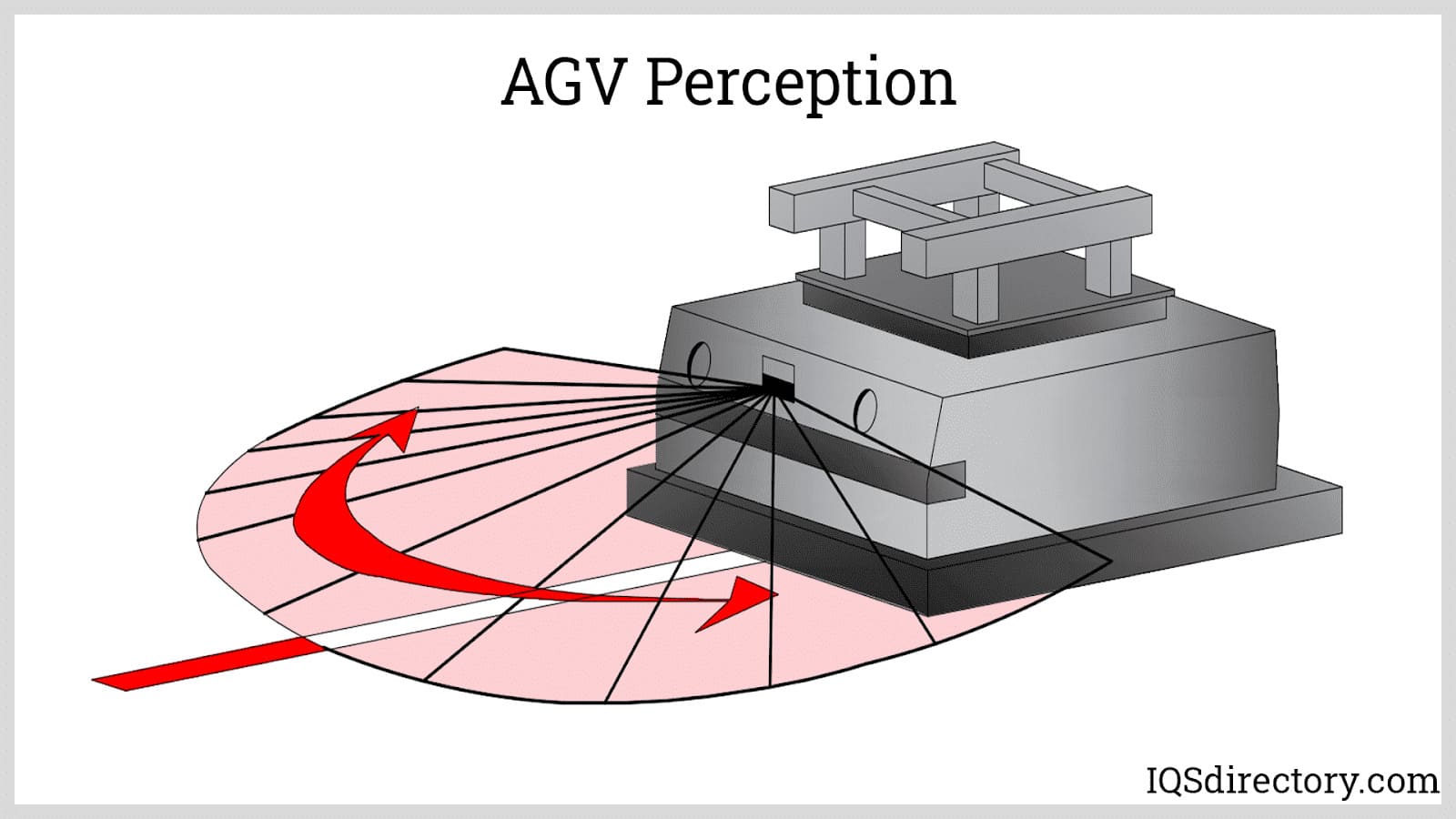

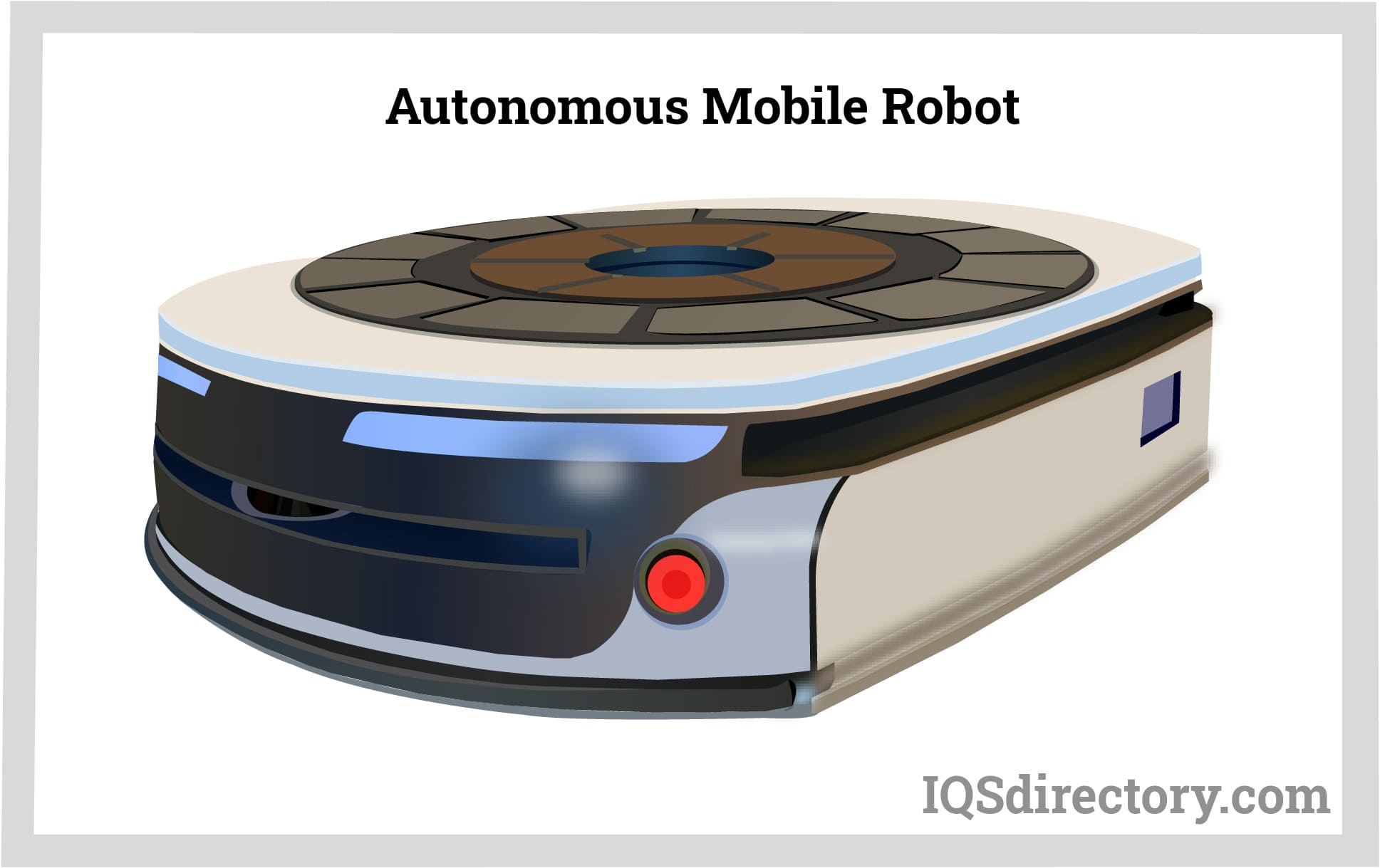

The autonomous guided vehicle systems are basically fixed guidance or free range. Fixed guidance systems use wire, magnetic tape or colored paint to guide the vehicles using antennae, frequencies and signal emissions. These are reliable and effective systems; however, the fixed route may not be suitable for some applications and limits the capabilities of the vehicles. Most AGV systems today are free range. These systems are computer controlled and often use laser guided vehicles which are able move around according to computerized instructions. They offer the benefit of flexibility as the internal navigation systems of the AGVs redirect the vehicle according to traffic or obstructions, allowing for smooth and safe operation.

For facilities with numerous AGVs, a traffic operating system and controller is necessary. Locator panels, CRT display and a central logging and report center are all used to monitor the location and movement of vehicles, and to determine system efficiency. The vehicles can also be equipped with an infrared detection sensor, and bumpers to protect the vehicle body in the case of collision.

As with any computer based system, a breakdown or malfunction in the software could cause a serious operating problem. AGV systems are a worthwhile addition to manufacturing processes despite the initial investment costs.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches