Automated guided vehicles (AGVs) have been around since the middle of the 1950s when trucks were attached to tracks of wires. As technology advanced, the wires have been replaced by magnetic tape, optical strips, and laser guidance systems.

Read More…America in Motion was founded in 2007 with a mission to bring customized automated vehicle designs and solutions to the masses. Serving customers in the fibers, paper, automotive, food, consumer products, heavy equipment, and general manufacturing. Our team specializes in fully customizable AGVs but also offers the option to build an automated vehicle by using a simplified modular approach (also...

With over 1700 mobile robotics deployed worldwide and with over 30 million miles accumulated, Oceaneering Mobile Robotics (OMR) delivers best-in-class solutions with the lowest total cost without sacrificing performance. For over 30 years, OMR has been a trusted partner of exclusive brands in the automotive, healthcare, manufacturing, and (intra-) logistics industries.

More Autonomous Mobile Robot Manufacturers

In each instance, AGVs were required to follow a track-type system that determined their path and destination. They were capable of moving products, inventory, pallets, and materials following the path of their track.

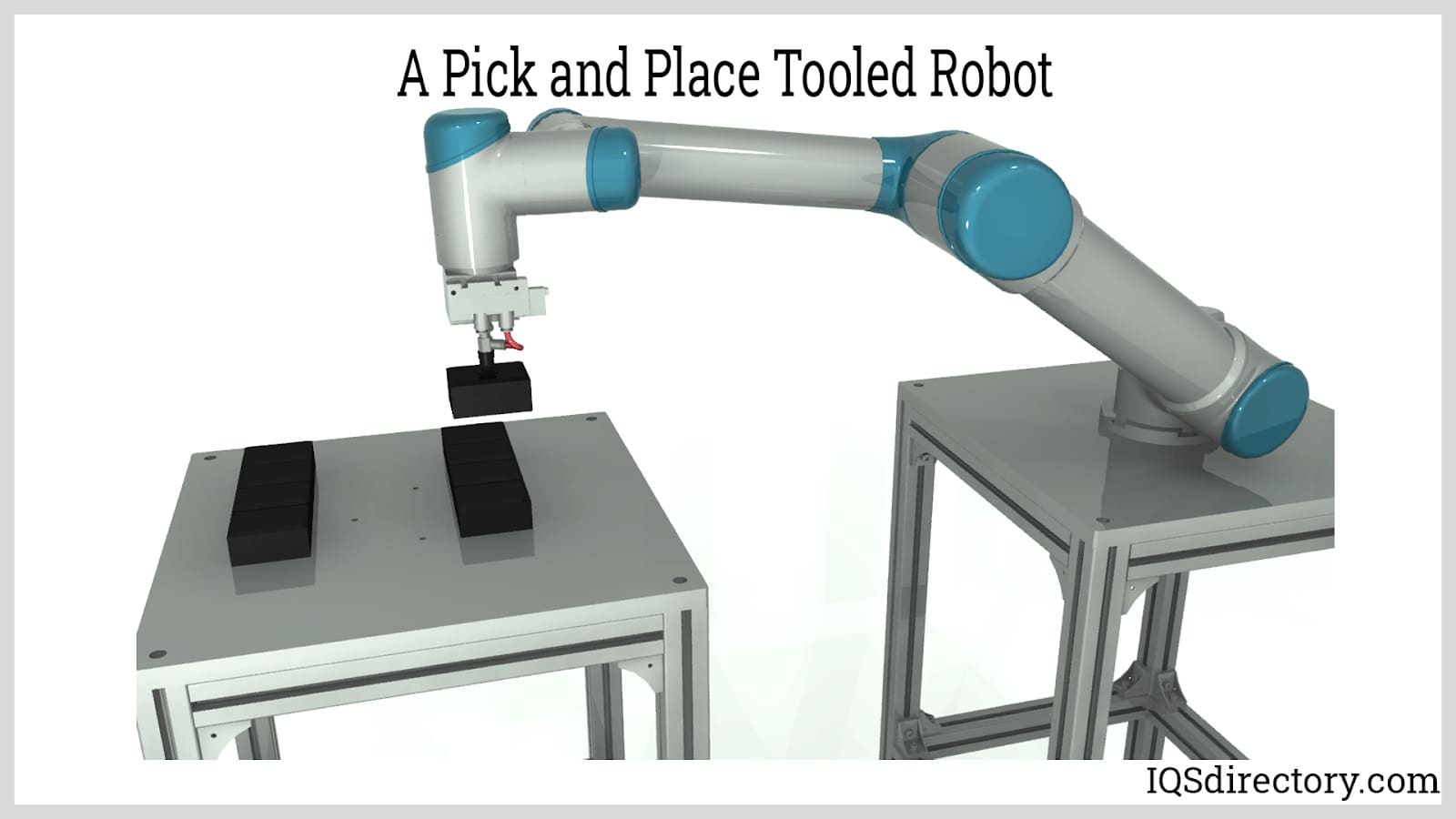

However, AGVs cannot move independently and must have a form of guidance system. They cannot “think” for themselves or vary from their assigned route. This limitation has been overcome with the development of autonomous mobile robots (AMRs) that can “observe” their environment and “see” obstacles using SLAM algorithms.

Initially, AMRs were used for tedious and repetitive tasks that took up workers’ time. As their technology has progressed, AMRs are now used for a wide array of functions, from protecting the safety of medical workers to supplying production lines. They are a form of technology that is becoming explored by many commercial and industrial facilities.

Reasons for Using Autonomous Mobile Robots

The use of AMRs is ever-expanding as more and more companies discover how valuable they can be. Warehousing makes extensive use of AMRs for picking, placing, and sorting orders. They are an excellent match for e-commerce. Shipping companies and healthcare facilities use AMRs to improve efficiency and precision and increase safety.

Safety

Many menial jobs have placed workers in dangerous or unhealthy conditions, causing great concern and harm. AMRs can be used to clean infected, contaminated, and hazardous areas or transport contagious laboratory specimens. In addition, heavy loads that cannot be easily moved by workers or forklifts can easily be moved using an AMR.

Flexibility

The flexibility of AMRs is one of their major selling points since they can be programmed, changed, and adjusted as needs arise. In contrast, AGVs require major changes to their guiding mechanism. With AMRs, changes can be programmed into their software with the onboard mapping and guiding sensors adjusting to meet new conditions. This aspect of AMRs makes them ideal for the constantly changing requirements of modern industry.

Efficiency

In modern business, efficiency is necessary to meet the needs of rapidly changing and growing markets. Functions that could once be handled in hours now must be completed in minutes. As the many needs of the supply chain and production increase, speed of fulfillment is the number one goal.

AMRs have the durability, precision, and accuracy to meet changing conditions and provide superior service. Users have been amazed at how quickly work can be completed using an AMR system.

Productivity

AMRs do not take breaks, need rest, or require time off. When their charge is low, they return to their charging station and are replaced by another unit. With an AMR, work progresses continuously at a steady pace, eliminating downtime and keeping production moving.

Reduced Cost

Aside from the initial investment in their purchase, AMRs have very few associated costs. They do not require leaves of absence, salaries, wages, or benefits. AMRs are a major step toward reducing labor costs while improving efficiency.

Environmentally Friendly

AMRs do not produce emissions that can contaminate the environment. Instead of fossil fuels, they are powered by electric motors that require recharging. Additionally, unlike other forms of industrial equipment, AMRs produce minimal noise.

How Autonomous Mobile Robots Navigate

AMRs use lasers, sensors, and cameras to navigate their surroundings. In addition, they use GPS movement, mapping software, and LiDAR, or programmed maps, to chart their location in conjunction with the lasers, cameras, and sensors. All of an AMR’s components work together to select the most efficient route to its destination and avoid uncharted obstacles, such as workers and other AMRs.

Uses for Autonomous Mobile Robots

The number of uses for AMRs is continually expanding as new technologies and innovations increase their effectiveness. When AMRs were first introduced, they were given simple yet time-consuming tasks. As they have improved and been programmed with more advanced skills, AMRs are used in many additional ways.

- Warehousing and Distribution – AMRs are ideal for warehouses and distribution centers since they can complete tasks quickly and efficiently, leaving time for workers to do other work. The AMR processes make searching for individual items far more efficient and productive.

- Cleaning – AMRs are a cost-effective way to clean contaminated and infected areas and complete daily cleaning chores without disrupting other activities. The technology of AMRs guarantees that every aspect of a complex can be cleaned and disinfected.

- Security – AMRs are used as replacements for security officers. Their sensors, cameras, and monitoring devices send a constant flow of data to the security control center, making it possible to observe large areas with minimal staff.

- Hospital Care – The healthcare industry relies on AMRs to deliver meals, linens, drugs, and sterilized supplies and to remove waste. Therefore, fewer people are needed in a healthcare facility, reducing the number of viruses and bacteria that enter an area.

- Hotels – Hotels use AMRs in the same way as hospitals to deliver food, drinks, linens, and information. Guests can be given a pin code to access an AMR when an item is being delivered. Consequently, AMRs save on the cost of personnel.

- Grocery Stores – The use of AMRs in grocery stores is a new avenue and is still being investigated. AMRs can help clean up spills and hazards, perform inventory control, and stock shelves.

- E-commerce – E-commerce has increased the need for faster deliveries with greater efficiency. AMRs are used to lower costs and decrease delivery times by picking, packaging, and shipping orders.

AGVs

AGVs Casters

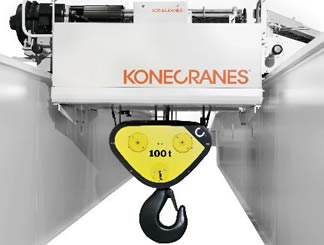

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches