General manufacturing, mail and newspaper, plastics, packaging, aerospace, automotive and food and beverage processing are some of the many fields that rely on automatic guided vehicles, also known as autonomous guided vehicles, to ensure smooth operations within manufacturing facilities and warehouses. Read More…

We invented the AGV in 1954 and offer the most affordable & versatile AGV capabilities. Our AGVs automatically transport pallets, racks, bins, totes, rolls, boxes, racks, etc. in all types of manufacturing and warehouse facilities. Our tape/target/structure-free, ‘virtual path’ navigation requires no floor path maintenance and does not use/require line-of-sight to often blocked building ...

America in Motion was founded in 2007 with a mission to bring customized automated vehicle designs and solutions to the masses. Serving customers in the fibers, paper, automotive, food, consumer products, heavy equipment, and general manufacturing. Our team specializes in fully customizable AGVs but also offers the option to build an automated vehicle by using a simplified modular approach (also...

With over 1700 mobile robotics deployed worldwide and with over 30 million miles accumulated, Oceaneering Mobile Robotics (OMR) delivers best-in-class solutions with the lowest total cost without sacrificing performance. For over 30 years, OMR has been a trusted partner of exclusive brands in the automotive, healthcare, manufacturing, and (intra-) logistics industries.

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

For over 30 years, companies have turned to RedViking for ways to increase throughput and minimize infrastructure. We are a leading AGV manufacturer, and our AGVs are efficient and user-friendly. Our AGV solutions are cleaner, more sustainable, and require less infrastructure than traditional conveyance methods. We can provide full custom design tooling for your AGV so it meets every requirement...

Fred Automated Guided Vehicles (AGVs) are built for manufacturing, distribution, and warehouse facilities to improve worker productivity and safety around materials movement, especially Point A to Point B workflows. Barcoding, Inc. designs, manufacturers, and supports the production of our robotics solutions in our Philadelphia, Pennsylvania office. Please contact us to discuss your needs and...

IDC Corporation produces a line of Automated Guided Carts (AGCs) for various industrial applications, including standard product line carts and custom-designed systems tailored to specific customer needs. The various models are built on a common control architecture that support various mechanical configurations, and support operations ranging from simple delivery loops to sophisticated...

Align specializes in heavy-duty, highly customized AGVs with capacities reaching over 1,000,000 lbs. Engineers work with you to develop a custom system that fits your unique application and facility needs. Align has been working with Fortune 500 companies since 1967 to make manufacturing inefficiencies a thing of the past and propel them into the future with AGV technology.

At SRSI - Slate River Systems Inc., we are proud to offer our advanced AGV products, designed to revolutionize your material handling processes. Our AGVs provide reliable, efficient, and flexible automation solutions, ensuring seamless integration into your operations. With precision navigation, robust safety features, and customizable configurations, our AGVs are ideal for optimizing workflows,...

Ward Ventures, Inc. designs and manufactures custom AGV equipment that your company requires. Our team provides a full turnkey service. We can help you be ready for your next project by designing, engineering and manufacturing to your new AGV to exact specifications. We have tough standards of reliability, safety and quality. No job is too big or small! Call today and get started.

More Automatic Guided Vehicle Manufacturers

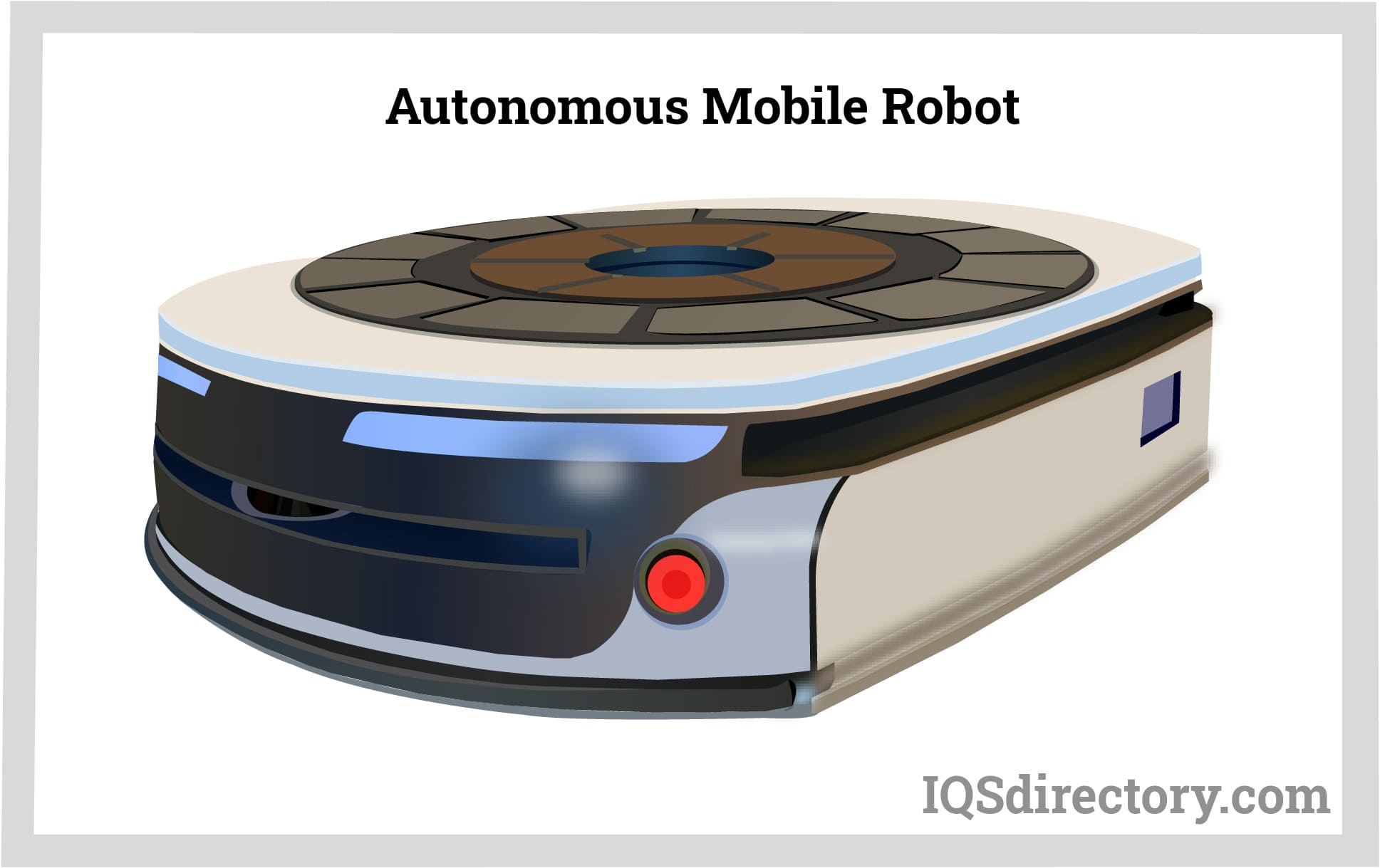

Automatic guided vehicles have become popular alternatives to more conventional material handling equipment such as forklift trucks, conveyor systems and manual push-carts. They are able to increase the productivity of a facility by providing more efficient movement and processes, and also cut back on the labor costs incurred by a manufacturing process as AGVs are able to work around the clock at higher rates than manual labor.

Automated guided vehicles can provide high volumes of repetitive and tedious movements. AGV Systems provide flexibility to a facility or warehouse as the capabilities of the guided vehicles are able to be customized to specific needs and changed as and when needed.

Basic guidance systems for AGVs include fixed path which uses wire, magnetic tape or paint to guide the vehicle along a specific route or path. Other control methods include computer software with inbuilt navigation capabilities which allow the vehicle to respond to data concerning traffic and/or potential obstacles, giving it time to redirect and avoid collision.

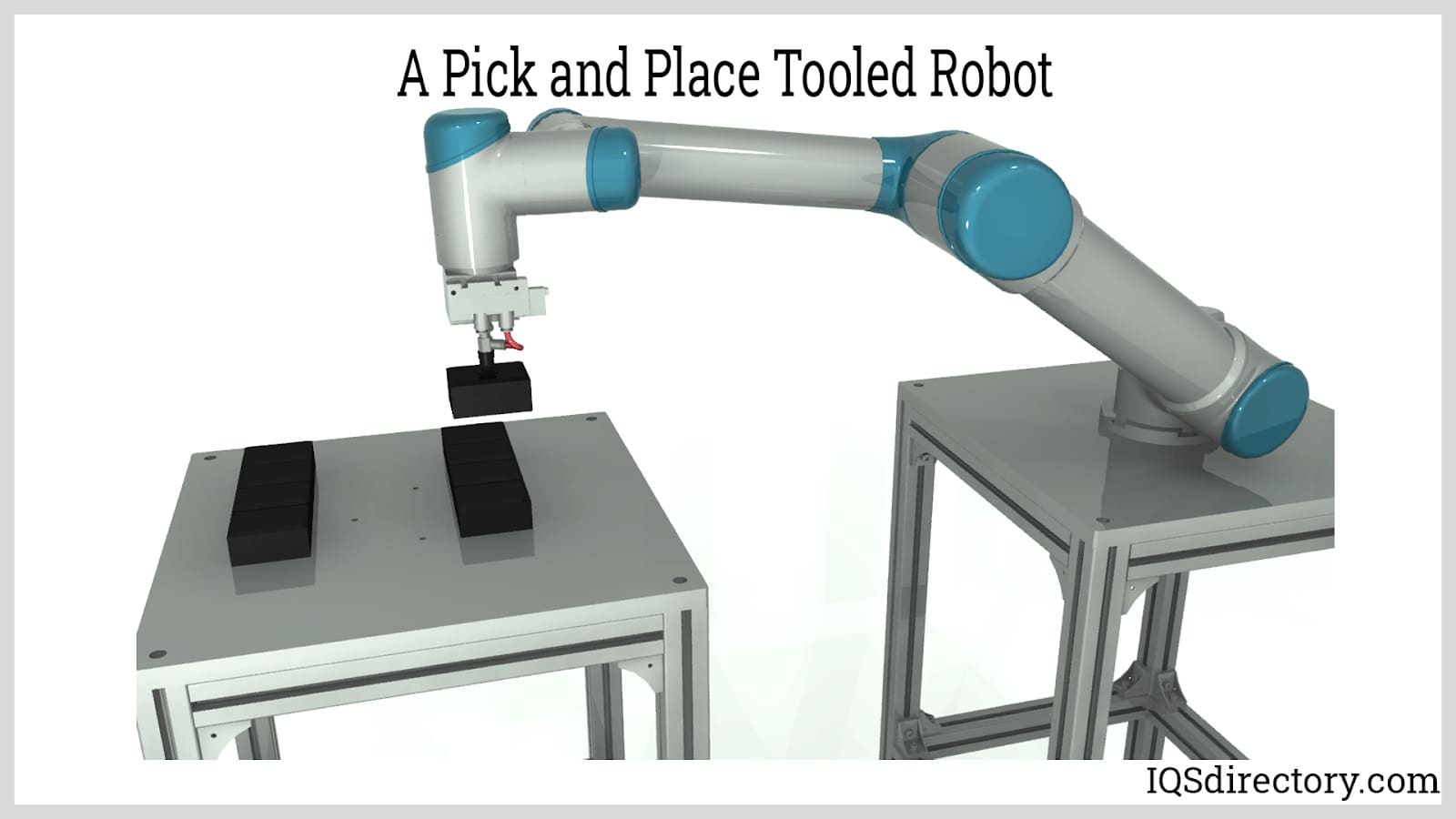

This technological development has further increased efficiency on the factory floor by improving safety and work flow. However, for computerized systems, especially those with multiple AGVs involved, a traffic operator is required to maintain control of the vehicles and to ensure there is not a breakdown or malfunction as this could cause a major problem. Other components can be added to AGVs to further adjust them to specific requirements or needs. They can range greatly in size and capacity from light load vehicles designed to work with electronic fabrication, parts assembly and light load transportation, up to large AGVs which are used to move heavy pallet loads.

The vehicles are typically powered by industrial strength batteries or electricity, although power requirements will vary according to application. AGV systems can be a costly investment and yet the benefits add up to make the costs worthwhile over time.

AGVs

AGVs Casters

Casters Cranes

Cranes Conveyors

Conveyors Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Platform Lifts

Platform Lifts AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches